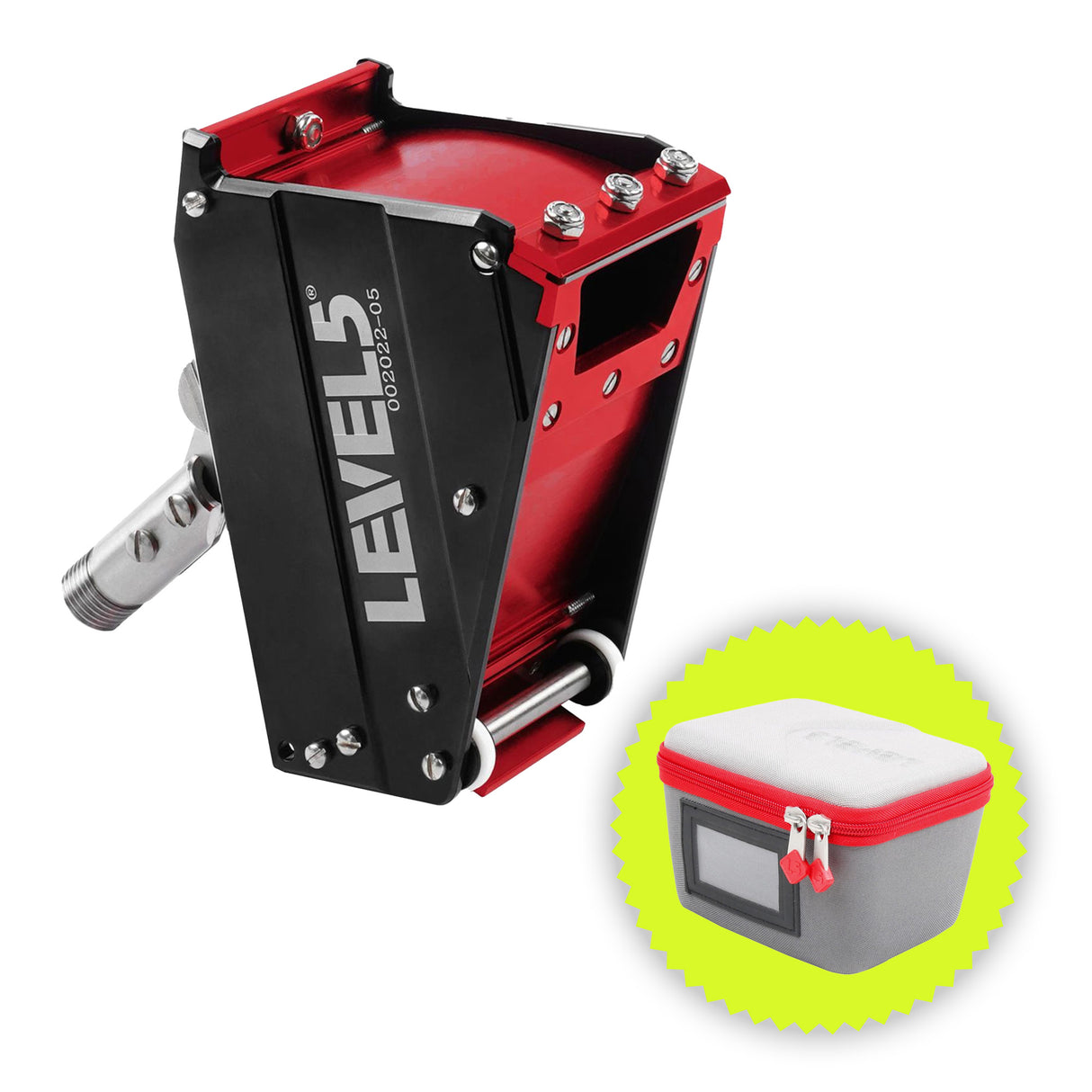

Level 5 Nail Spotter (2nd Gen) with Bonus Storage Case

Level 5 Nail Spotter (2nd Gen) with Bonus Storage Case - 2" is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

LEVEL5 nail spotters are used to quickly fill and finish fastener indentations during the drywall finishing process.

- PLEASE NOTE: The 2nd Generation LEVEL5 nail spotters now fit LEVEL5 corner roller handles (SKUs 4-777, 4-792 and 4-796)

- HIGH-QUALITY DESIGN | Easy to operate and clean, LEVEL5's efficient design saves you time while improving finish quality when covering nails and screw holes.

- PREMIUM MATERIALS | High-quality stainless steel construction, urethane wiper seal, and high-carbon steel blade for precise coating and a long life.

With a nail spotter, you can fill and finish an entire row of fastener indentations (screw or nail) in a single pass. The process is much easier and faster than if you were doing it using traditional hand finishing tools, and typically much less sanding is required afterwards. With a nail spotter you also have additional reach, which means you can fill fastener indentations on high walls and ceilings without the use of stilts.

The wheels on a nail spotter head allow it to run smoothly on the surface of the drywall, as well as glide over joints without tearing the tape.

Nail spotting is typically performed in two or three thin coats. Although there is no definitive rules regarding which box size to use for each coat, we suggest the following to minimize sanding:

- 2” Width - One or two underlying fill coats

- 3” Width - Final skim coat to feather out the edges

Usage Tips

- Nail spotting should be the first step in the drywall finishing process. This way you can do full passes without interruption due to freshly filled joints.

- Run your nail spotter passes in the same direction as your drywall butt joints.

- Prior to using your nail spotter, run a joint knife along the surface of the drywall to make sure none of the fasteners are protruding. Protruding fasteners will not finish properly and also have the potential to damage the carbide steel blade on the nail spotter.

- Before using the nail spotter, lubricate the sweep gasket to ensure the pressure lid is moving freely before filling the head with joint compound. We recommend using 3-in-1 machine oil (do not use WD-40, as it is caustic and will damage rubber and urethane gaskets over time).

- For easier use (and less potential mess), only fill up the nail spotter to approximately 80% of its capacity so that it sits just below the compound dispensing slot.

- The correct compound thickness for nail spotting is all about balance. You want to make sure that the compound is thin enough that it doesn’t take a lot of effort to get it to flow evenly out of the dispensing slot, but not so thin that you are seeing ridges or drips on the outside edges of each pass.

Features

- Cover nail and screw spots with precision

- Robust design makes operation and cleaning easy

- Improves quality of finish

- Durable stainless steel construction

- Lightweight and mobile build

- Wiper seal made of premium urethane

- High carbon blades last longer and provide precise coating