A flat box is used in conjunction with a flat box handle to efficiently apply a crowned, feathered coat of joint compound over taped flat seams on walls and ceilings.

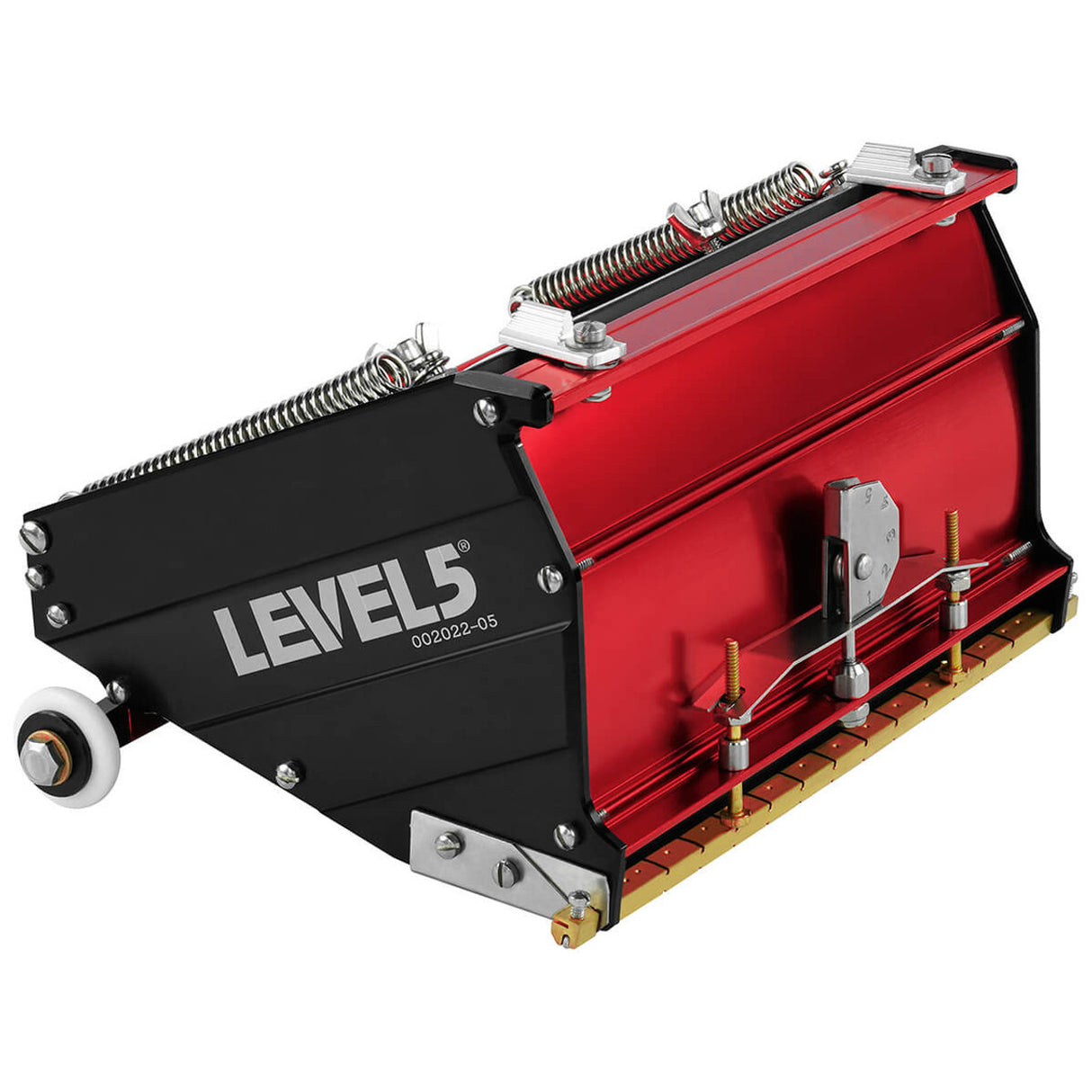

LEVEL5 flat boxes feature a premium-grade aluminum housing that has been anodized for extreme durability and easy cleaning. They are fitted with a flexible brass blade holder and a stainless steel blade, as well as stainless steel skids and shoes. A crown adjustment dial provides six settings (including “wide open”), so the ideal amount of compound can be dispensed on the wall to ensure consistent, professional results.

LEVEL5 flat boxes have a premium composite pressure plate seal and beveled edges on the box housing ensure easy open and close. The pressure plate itself also opens extra wide for easy cleaning.

LEVEL5 flat boxes are outfitted with non-marring wheels with durable bearings for ultra-smooth operation.

MEGA CAPACITY FLAT BOXES

The MEGA capacity flat boxes can hold approximately 30% more compound than standard capacity flat boxes, enabling few trips back and forth to the pump. The trade off is that MEGA capacity flat boxes are bulkier and heavier when full due to their increased height. Ultimately, the choice between the two styles is a matter of personal preference.

2ND GENERATION ENHANCEMENTS

- Both the standard and MEGA capacity flat boxes feature higher compound capacities than previous generation.

- All structural components are higher-gauge, aircraft-grade aluminum for durability, even under heavy commercial use.

- New precision-machined billet aluminum body and side plates with bevelled edges.

- Side plates are now black hard-coat anodized, significantly reducing the friction against the sweep gasket and lowering required push force.

- New proprietary urethane sweep gasket provides less resistance, smoother operation and a better seal.

- New hinged pressure plate provides a consistent push radius at all compound capacity levels.

- Hinge opens wide for easy cleaning.

- New high-durometer urethane rubber tires for more longevity.

TIPS & TRICKS

- Consistency of Compound - There are no strict guidelines for the consistency of the compound when using flat boxes, as it is a matter of personal preference. It is crucial to ensure that the compound is thick enough to avoid dripping down the walls or overflowing from the dispensing slot, but thin enough to be applied without excessive force. Some finishers prefer to use different consistencies depending on the surface they are working on (walls or ceilings).

- Filling the Flat Box - The ideal way to fill the flat box is through the dispensing slot with a compound pump (#4-771) and a filler valve equipped with a flat box filler nozzle (both are included with the pump). It is also possible to manually fill the box by opening the hinged pressure plate.

- Flat Box Handles - Flat box handles have a pinch break feature which enables you to lock the box at a specific angle and maintain it flat against the wall. To activate this mechanism, squeeze the trigger located at the end of the handle. PRO TIP: to prevent injury, keep light pressure on the pinch brake trigger when the flat box is not in use to avoid swinging and accidental contact with your knuckles or fingers.

- First Coat - The first coat should be a "fill" coat, using the lowest crown setting of your choice (out of the 6 crown options). The purpose of this coat is to completely cover the tape and conceal the tape bevels. If you come across any air pockets or other imperfections, simply apply one or more passes over the seam until you are satisfied with the result.

- Second Coat - After the first coat has dried, a second, thin layer can be applied using a slightly wider flat box to fill any imperfections and feather out the compound to hide the seam.

- Final Result - When performed correctly, only two coats should be necessary, with minimal sanding required afterwards to achieve a professional finish.